Special Cutting Tools

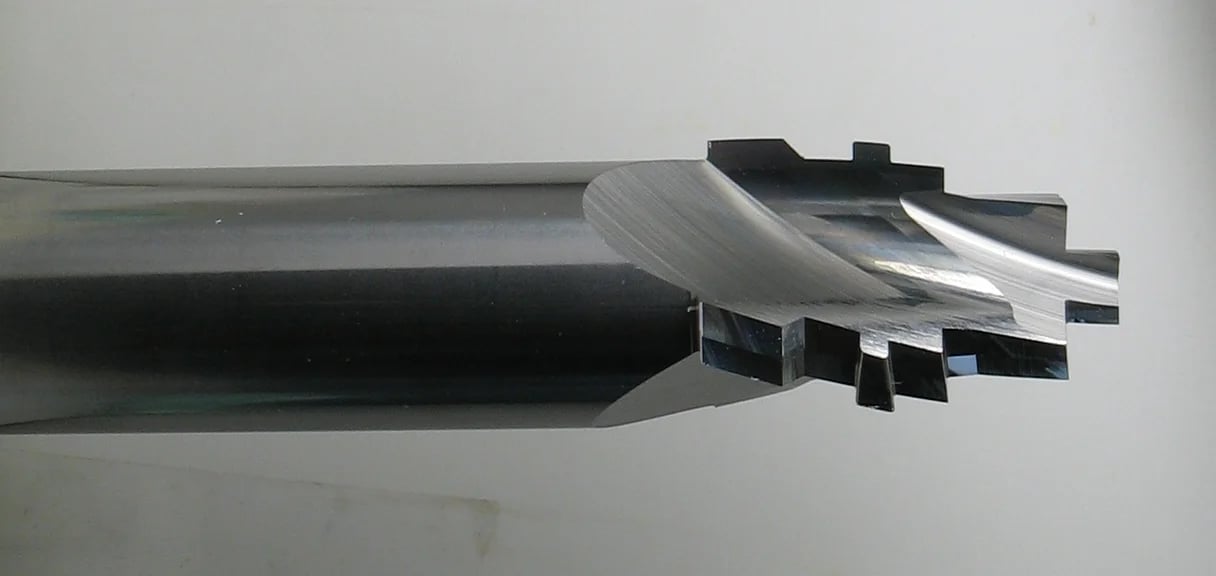

Are you in search of a custom drill, a bespoke boring bar, or a form milling cutter? Look no further than Rainford! We understand that one size doesn't fit all and that relying on standard tools can sometimes lead to inefficient and unreliable processes.

Whether you're aiming to reduce cycle time by integrating two features into one tool for an existing application or implementing a completely new production process, we've got you covered.

Our team specialises in designing and manufacturing innovative tools tailored to your exact requirements. Our goal is to help you not only secure more orders but also optimise your processes for greater efficiency.

WHY CHOOSE RAINFORD PRECISION

Work with leading suppliers

Create high-quality and cost-effective custom solutions

Bespoke tools to increase reliability of process or for novel applications and specific purposes

Over 30 years of expertise producing precision tools

Design and build custom precision tools with fast deliveries

First-class customer service from experienced engineers

ISO 9001 certified

Download ATOM Drills Vol 9.1 Catalogue

Download for free today

For over 25 years Rainford Precision Machines has supplied precision tooling of the highest quality to the precision engineering industry, forming strong relationships with suppliers and clients alike.

Fill in the provided form to download this FREE guide

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

Book A Consultation

Revolutionise your machine drilling operations today! Take the first step by booking a consultation and a member of our seasoned team will analyse and optimise your processes, recommending cutting-edge technologies for enhanced precision and productivity.

.png?width=2563&height=2351&name=KERN-Ametek-logo-rot-schwarz%20(1).png)

.png?width=500&height=200&name=PEMtec%20Logo%20(1).png)

.png?width=500&height=200&name=Benzinger%20Logo%20(1).png)

Interested In Our Products?

GET ACCESS TO OUR WIDE RANGE OF PRODUCT BROCHURES

Latest From The Blog

2 min read

Fuelling Innovation In Medical Equipment Manufacturing With High Precision Cutting Tools

Apr 25, 2025 by Rainford Precision

2 min read

Louis Belet: Precision Tools For Every Stage Of Watchmaking

Apr 21, 2025 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)