We understand the problems you can face - from tools that wear out too quickly, break too easily or that provide inconsistent bores to poor surface finish. Eliminate the effort and cost of regular resetting by ensuring you use a high quality boring bar system.

Using our expertise and incredibly high-quality boring bars, we can create processes which eliminate errors and dramatically improve repeatability. As the demand for ever smaller components continues to grow, so has our range of boring bars that are all designed with pinpoint precision from leading manufacturers DTS GmbH and HOBE.

Why choose Rainford?

Extensive range of boring bars from leading suppliers

Long tool life with high reliability

We can create more accurate applications and efficient processes

Great communication and customer service

Supply of standard boring bars in just 5 days (specials may take 6-8 weeks)

ISO 9001 certified

Download ATOM Drills Vol 9.1 Catalogue

Download for free today

For over 25 years Rainford Precision Machines has supplied precision tooling of the highest quality to the precision engineering industry, forming strong relationships with suppliers and clients alike.

Fill in the provided form to download this FREE guide

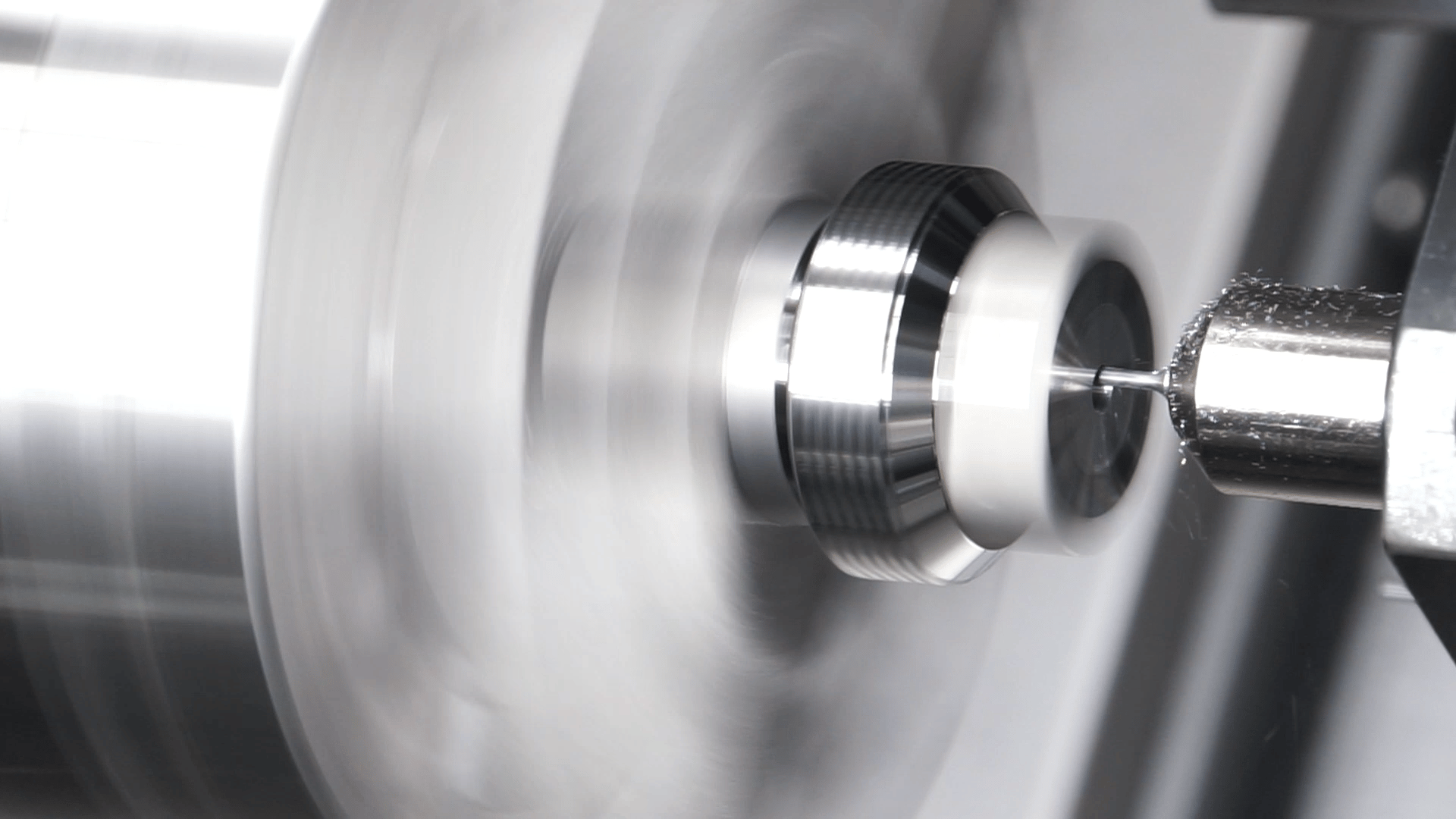

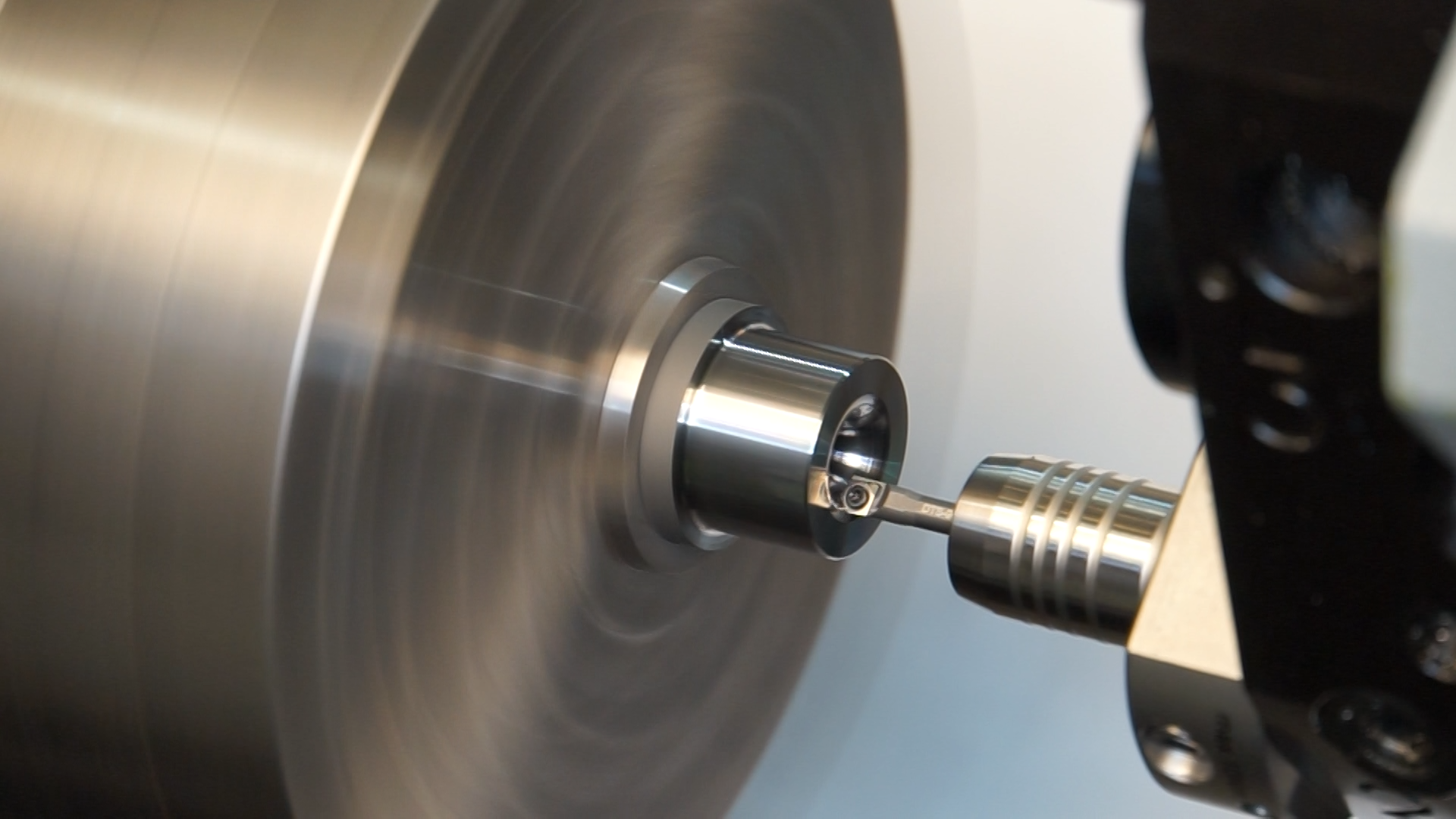

Our Boring Bar Range

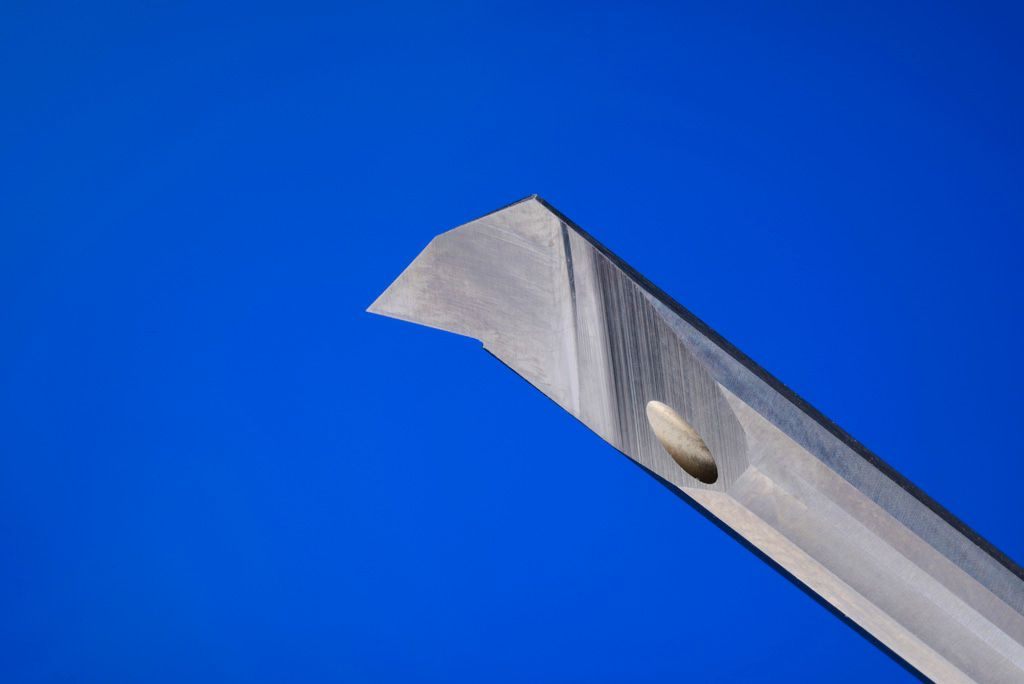

Brazed PCD, CVD-D, UltraDiamond and CBN boring bars from DTS GmbH are suitable for machining bores from Ø1,00mm and can be used for turning in the lathe and in the spindle of a milling machine. They work with a huge range of materials – carbide, tungsten, steel, plexiglass, ceramic, aluminium, titanium, copper, plastics, glass, graphite and many more. Their exchangeable tip boring bars are suitable for a minimum bore of Ø3.50mm upwards.

HOBE produces solid carbide boring tools for many different internal processes in bores down to 0.33mm. They’re available either coated or uncoated, in left or right-handed versions, and come in standard or extended lengths. The tool holders with internal coolant supply for manual tool change are ingeniously designed, offering a remarkable repeatability of ± 5 µm without requiring re-calibration during insert change. Their precision and reliability make them an invaluable asset for any application.

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

Book A Consultation

Revolutionise your machine drilling operations today! Take the first step by booking a consultation and a member of our seasoned team will analyse and optimise your processes, recommending cutting-edge technologies for enhanced precision and productivity.

.png?width=2563&height=2351&name=KERN-Ametek-logo-rot-schwarz%20(1).png)

Interested In Our Products?

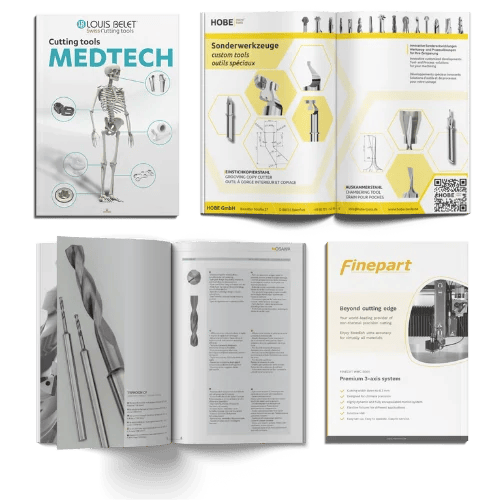

GET ACCESS TO OUR WIDE RANGE OF PRODUCT BROCHURES

Latest From The Blog

2 min read

Fuelling Innovation In Medical Equipment Manufacturing With High Precision Cutting Tools

Apr 25, 2025 by Rainford Precision

2 min read

Louis Belet: Precision Tools For Every Stage Of Watchmaking

Apr 21, 2025 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)