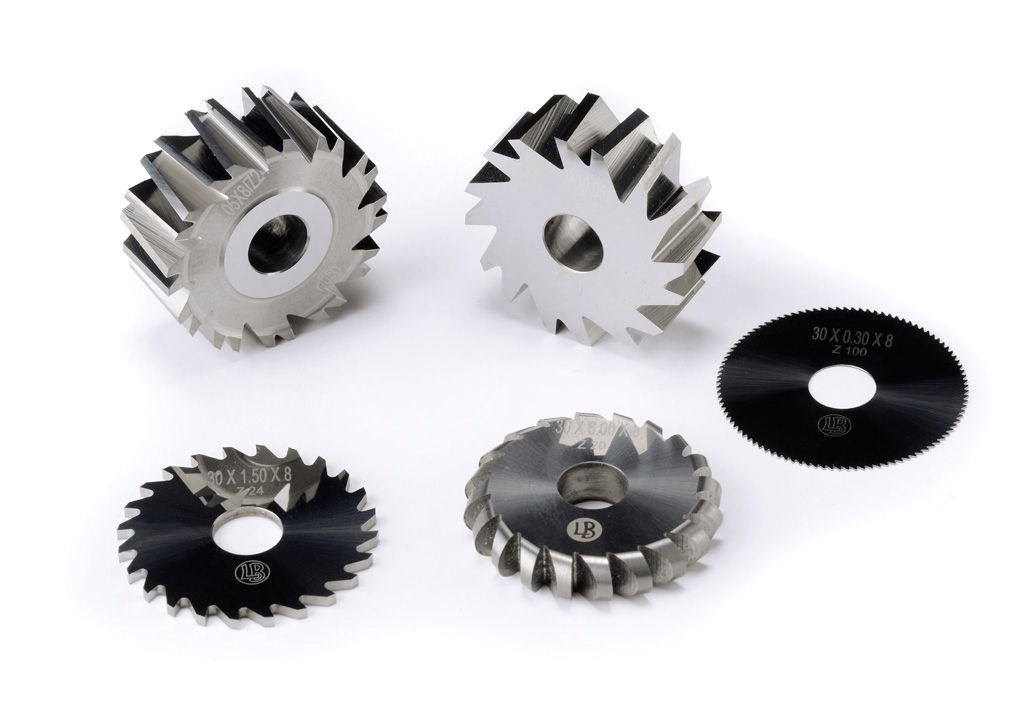

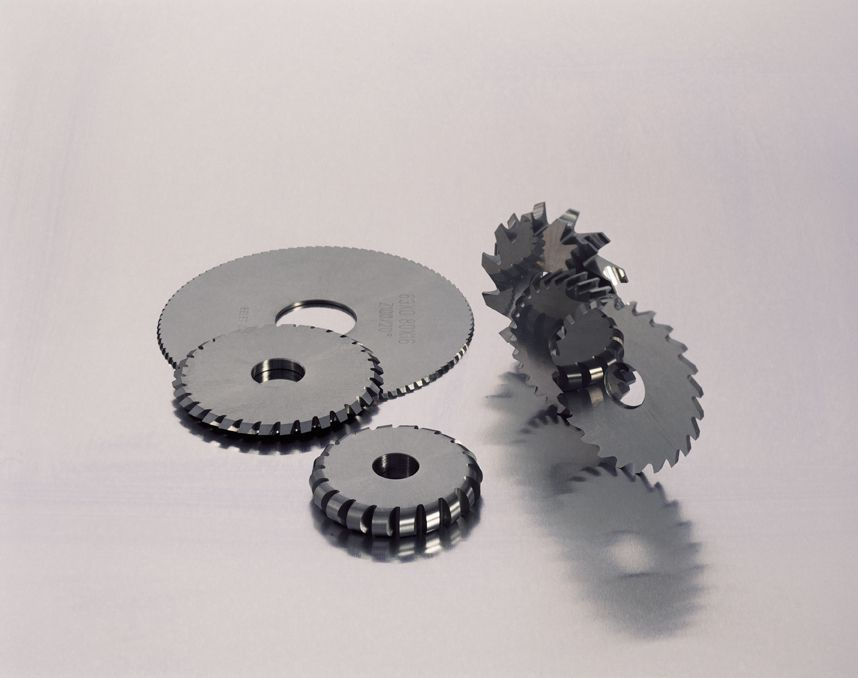

Solid Carbide Slitting Saws

What Are Slitting Saws?

Slitting saws are ideal when a thin deep cut is required, whatever material you are looking to process. Their design and rigidity make them suitable for both materials that are easy to machine and those which are more challenging.

As demand has increased for durable and precision-focussed cutting tools, our range of slitting saws has grown substantially. We work closely with leading global suppliers to source solid carbide slitting saws with many diameters, widths and teeth numbers to optimise the process or application.

Why Choose Our Solid Carbide Slitting Saws

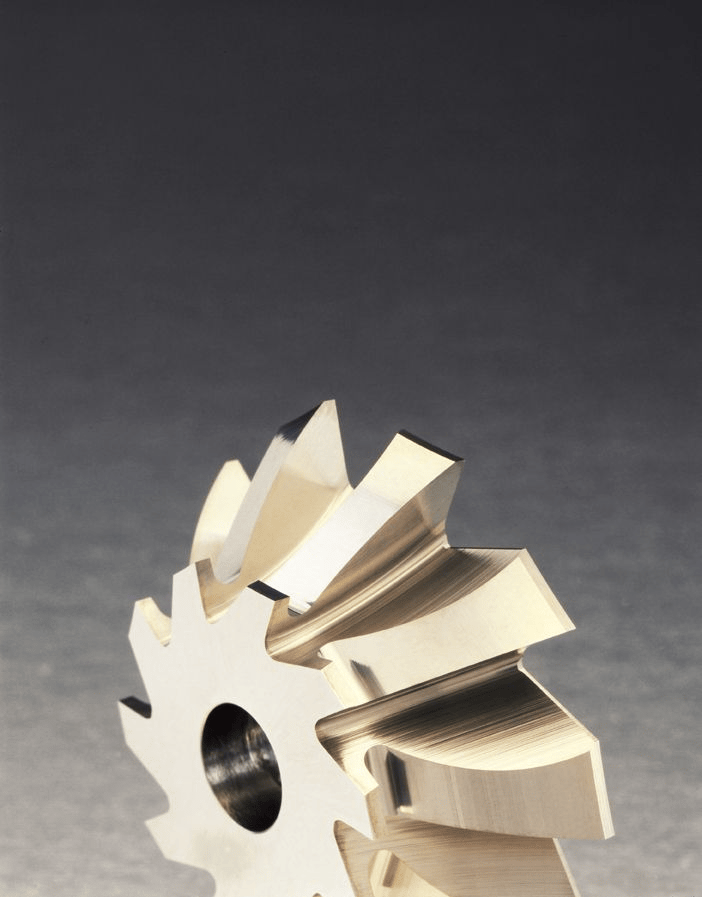

Made from solid carbide, providing superior rigidity compared to the cutting performance of a high-speed steel (HSS) saw

Longer tool life than HSS saws, cutting through abrasive materials more efficiently and reduce cycle time

Available in widths starting from 0.1mm, in increments as small as 0.01mm

Tooth forms can be straight, helical or staggered

Available as single angle or double angle forms along with full form radius (concave and convex) cutters from 0.2mm to 6.0mm wide.

Can be supplied uncoated or coated to suit the application

Precision arbours available to complement the saws

Whether you're a current customer seeking a slitting saw tailored to your specific needs or a business seeking expert guidance, Rainford is here to assist. We specialise in designing and implementing processes that optimise production while upholding the highest standards of quality and finish.

Why YOU Should choose Rainford?

Vast range of high-quality saws to suit many different applications

Long tool life to improve the efficacy of your process

Made from ultra-fine grain carbide, which can be coated or uncoated

ISO 9001 certified

Download ATOM Drills Vol 9.1 Catalogue

Download for free today

For over 25 years Rainford Precision Machines has supplied precision tooling of the highest quality to the precision engineering industry, forming strong relationships with suppliers and clients alike.

Fill in the provided form to download this FREE guide

Why We Do What We Do

I would like to say thank you for your assistance so far. We have only drilled 4 x 0.80mm holes 50d deep but the fact they worked the first time was appreciated by everyone.

We use OSG mainly but when we have a specific job that needs doing, we come to Rainford Precision because they are and do the Crème De La Crème of Products and services.

The End Mill was an ideal choice due to the unusual shape and the need to have a small radius. They turned out great, and the surface finish is really good.

I would like to say thank you for the help you have given our project over the last few years. Your advice on the correct cutters plus the right speeds and feeds has not only helped with accuracy but brought the cycle times down so we can meet our project deadlines.

Thank you for making that so incredibly easy and prompt.

We received your delivery this morning as you had promised to do for us, thanks for that, it is great when a plan comes together.

A diamond service from Rainford as usual. The success of our company is very much down to the external support received from Key organisations such as Rainford Precision. Your company is one of the first I will always turn to assist us.

.png?width=2563&height=2351&name=KERN-Ametek-logo-rot-schwarz%20(1).png)

.png?width=500&height=200&name=PEMtec%20Logo%20(1).png)

.png?width=500&height=200&name=Benzinger%20Logo%20(1).png)

Download Your Free Copy!

.png)

Our FREE guide, 'The Guide To Avoiding Common Precision Cutting Tool Mistakes,' offers invaluable advice on avoiding costly cutting tool mistakes and optimising your machining operations.

- Eliminate Dimensional Inaccuracies

- Master Speeds & Feeds

- Troubleshoot Cutting Issues

- Extend Tool Life & Reduce Downtime

Interested In Our Products?

GET ACCESS TO OUR WIDE RANGE OF PRODUCT BROCHURES

Latest From The Blog

2 min read

Applications Driving Demand For Ultra-Fine Carbide Grades

Jan 8, 2026 by Rainford Precision

5 min read

Electrochemical Production Of Precision Parts At Scerox EDM Technology

Jan 5, 2026 by Rainford Precision

.webp?width=500&height=208&name=Rainford%20Precision%20Logo%20(1).webp)