Rainford In Good Health For MedTech Show

Rainford Precision will highlight its reputation as a leader in ultra-high precision micro-machining at the forthcoming Medical Technology Ireland...

2 min read

Rainford Precision : May 2, 2024 11:00:00 AM

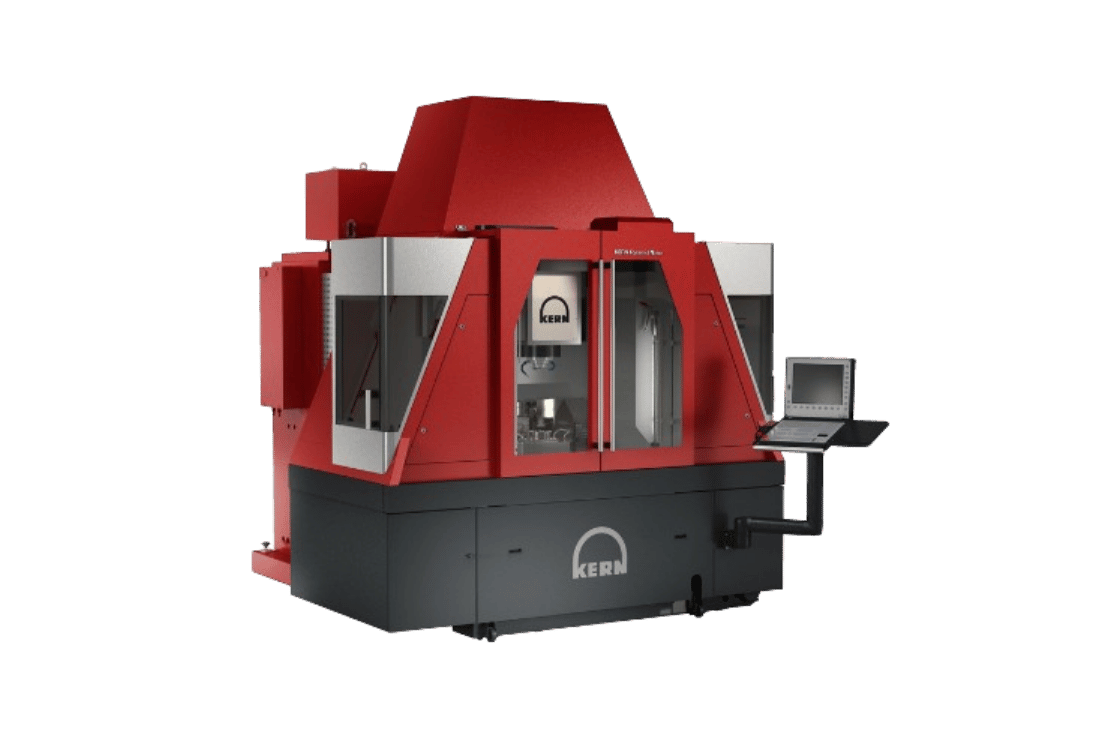

Kern Microtechnik is well-known as one of the world’s leading manufacturers of precision CNC machining centres. Its machines reach levels of accuracy unmatched by many others and the Kern Pyramid Nano is considered one of its crowning masterpieces.

Here, we take a deep dive into the benefits of the KERN Pyramid Nano, the key advantages it offers and why it’s a solid investment for any precision engineering company.

Deep in Bavaria lies Eschenlohe, a small village peppered with traditional German buildings and surrounded by breath-taking views of the Alps. With its late baroque church and pretty houses it’s hard to imagine such a place being at the forefront of machine tool technology but it is also home to Kern’s machine tool building plant and some of the world’s most exciting developments in the ultra precision machining technology field.

Started in 1962, Kern originally built their reputation supplying high precision components but the precision machines at the time were not accurate or productive enough for its engineers. So, in 1982 the company took the bold step of developing its own machining centres.

Their first micro-drilling machine reliably achieved accuracies in the range of 0.001mm, amazing customers who immediately wanted to buy the machines. Buoyed by this success Kern has gone on to develop the Kern Evo, the Kern Micro and of course, the Kern Pyramid Nano, which has enabled the company to dominate the market in ultra precision machine tools.

Kern is also unique in that it still has a subcontract factory, based in Murnau-Westried, where Kern machine tools are used to supply components to companies around the world. Lessons learned, whilst using the machines in the subcontract facility, are fed back to the designers of the machines to improve the products further.

Robust Construction - Built with KERN ARMORITH®, the Pyramid Nano has exceptional damping and strength, along with a symmetrical portal design for thermo symmetrical stability and rigidity.

High Precision and Surface Quality - Equipped with hydrostatic guideways and drives, eliminating friction and wear. This translates to unmatched positioning accuracy (down to 0.1 microns) and exceptional surface finishes

Intelligent Temperature Management - The Pyramid Nano incorporates an advanced temperature management system, crucial for maintaining consistent precision by stabilising thermal conditions during operations.

Versatile & Automated Operations - Offers operational versatility with both 3-axis and 5-axis models available, along with automation features like integrated tool and workpiece changers for extended unattended operation.

Technical Specifications - Features the smallest travel increment of 0.1 μm, with XY and Z Axis travels, and a tool change time of just three seconds

Jig Grinding Package Available - Allows for a wider range of machining tasks beyond its standard milling or machining functions, adding more versatility and capability.

The Kern Pyramid Nano offers a wealth of advantages including:

Increased precision with milling and grinding within one set-up as well as a reduction of cycle times. It enjoys high flexibility with programmable grinding contours and has the highest precision grinding of steps even in the pendulum stroke of the Z-axis.

Its automation capabilities mean it can run 24/7, significantly increasing output.

Excellent return on investment thanks to increased productivity rates, lower energy costs and accuracy.

The Pyramid Nano also boasts high stiffness, superior temperature control, the highest vibration damping and lower costs.

Hydrostatic guides mean no friction, no stick-slip effect and no wear.

Ergonomic design of the Pyramid Nano ensures optimum accessibility and clamping as well as safe and ergonomic working for operators.

Discover the incredible power of the Kern Pyramid Nano with Rainford Precision and experience the pinnacle of machining technology. Contact our team today!

Rainford Precision will highlight its reputation as a leader in ultra-high precision micro-machining at the forthcoming Medical Technology Ireland...

Rainford Precision Machines Limited, the UK-based leader in high-precision cutting tools and machining solutions, has established itself as a trusted...

The evolution of manufacturing technology has created unprecedented demand for complex, precise components across a vast range of different...