1 min read

Rainford’s New Range is Saw Good

For machine shops producing small precise components, Rainford Precision is now introducing the new Louis Belet range of circular slitting saws. The...

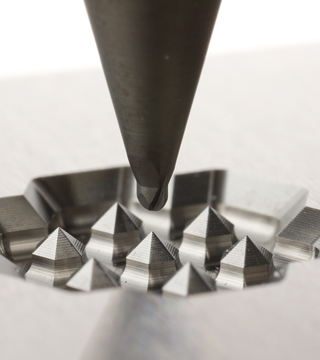

With the micro manufacturing industry continually growing in the UK, micro machining experts Rainford Precision have now launched a six page report to assist manufacturers in the drilling of micro holes. The new technical report is also supported by a new website www.precisiondrills.co.uk. Both the report and website have been launched to advise industry with regard to the potential pitfalls and the machining variables when drilling holes below 1mm diameter.

Deciding upon the type of drill to use is only one of the parameters in achieving the perfect hole size, accuracy and concentricity. As a leading authority in Micro Machining, Rainford Precision’s Managing Director, Mr Arthur Turner has identified the numerous factors that customers often fail to consider when machining in the ‘micro’ range.

The report highlights how end users can reduce tooling costs by over 40% whilst eliminating scrap and improving productivity, hole quality and accuracy. Micro machining requires a different philosophy and mindset in the machine shop and the Rainford Precision report highlights some key points such as checking the accuracy and concentricity of the machine spindle and whether the component face is perpendicular to the drill.

The report emphasises the importance of machine rigidity and for turning centres the issue of drilling on centreline with no pips on the face to be drilled. When these factors are considered, the critical element is the type of drill to use on the chosen workpiece material. Customers too often think a ‘drill is just a drill’. Wrong! With the option of HSS and carbide drills, coated or uncoated, drill rigidity, length to diameter ratio, hole depth, drill point angle and the clamping of the drill as just a few of the issues highlighted in the technical report; manufacturers that are serious about micro machining would be wise to take advice from a micro manufacturing expert and review the report.

As the UK’s leading supplier of micro machining drills and cutters with drills from 0.1 to 2mm in 0.01mm increments, Rainford Precision has the wealth of experience and expertise that is beyond the realms of most cutting tool manufacturers. To find out how you can benefit from this expertise, please visit for your free copy of the report.

1 min read

For machine shops producing small precise components, Rainford Precision is now introducing the new Louis Belet range of circular slitting saws. The...

Building upon the success of the Union Tool range of hard milling tools, Rainford Precision is now delighted to announce the arrival of a new range...

Rainford Precision, the UK’s leading supplier of cutting tools and machine tools for the micro machining industry has now launched a new website. The...