The Cutting Edge Of Precision: A Deep Dive Into The Kern Pyramid Nano

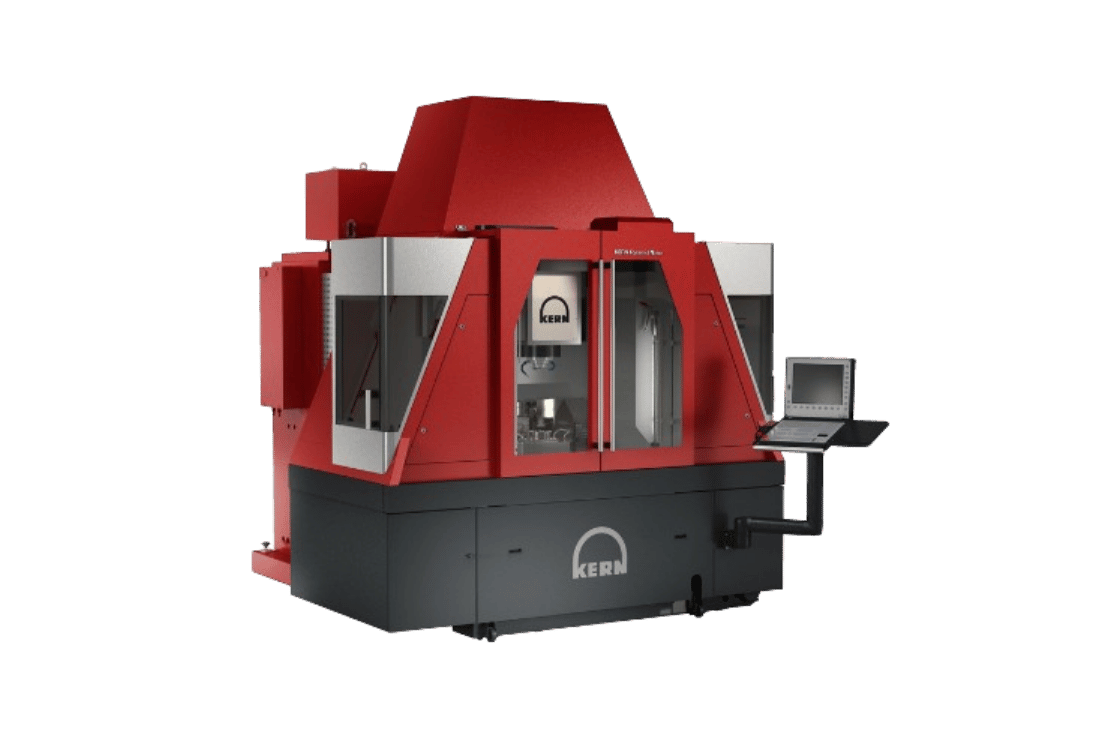

Kern Microtechnik is well-known as one of the world’s leading manufacturers of precision CNC machining centres.

2 min read

Rainford Precision : Mar 21, 2024 11:00:00 AM

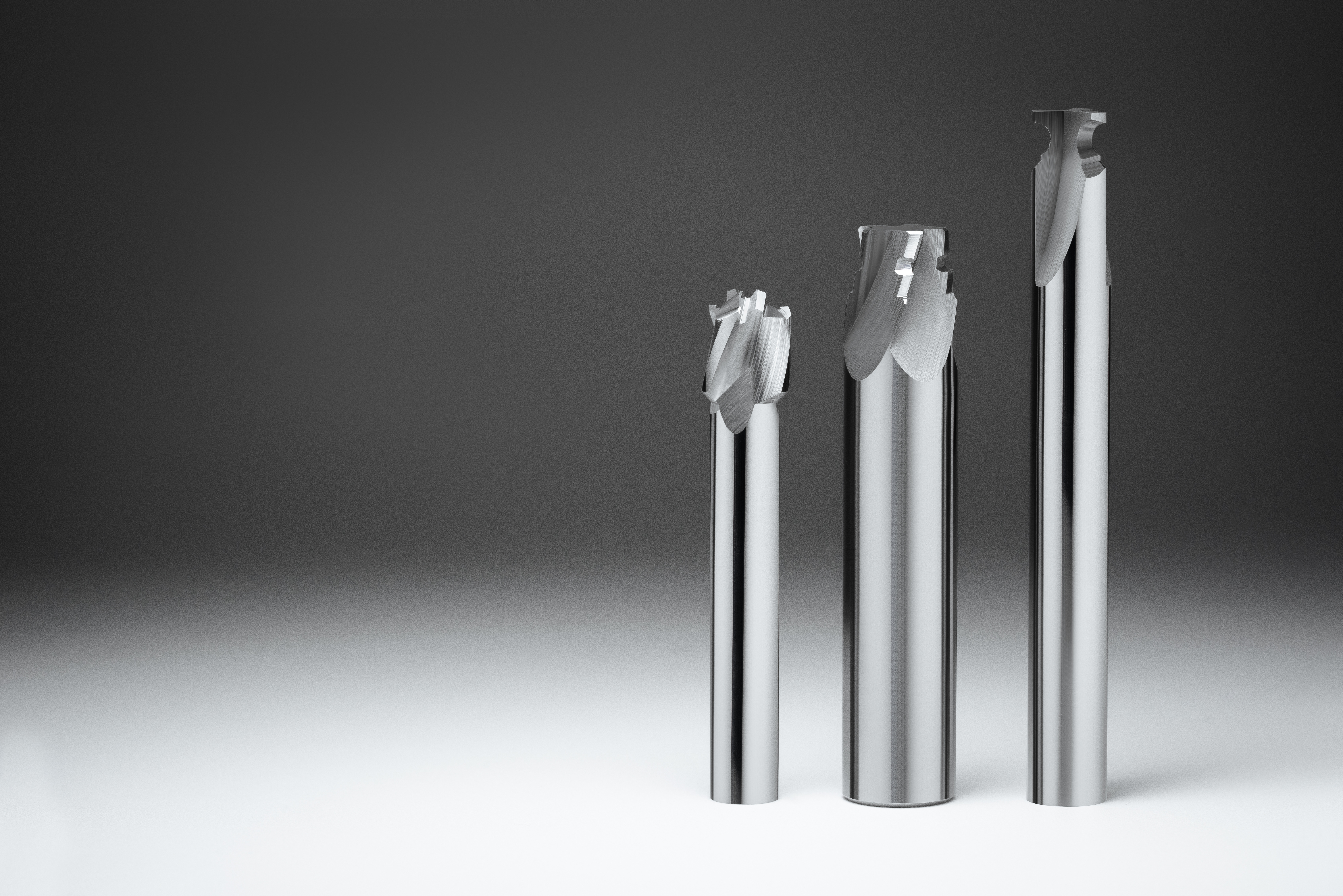

While standard tools suffice for many tasks, there are instances where something unique is required. Be it for combining operations, working with irregular forms, or just a long reach application then special cutting tools emerge as the solution.

But when you choose to have custom tools made, ensuring optimal functionality is essential. That’s why, at Rainford Precision, we embark on a collaborative journey with our clients, working through the refinement of the tool so it matches your exact requirements.

No matter how good the functionality of standard tools may be, they do have their limitations. For most applications they will be perfectly fine but for certain processes they simply won’t fit the bill or there is a better solution to be provided by using a special tool. For example, if you’re looking to reduce cycle time on a component by combining operations, a special cutting tool will be the answer.

Adapting existing tools, although great for quick solutions, can be a little like trying to fit a square peg in a round hole. A bespoke tool will not only improve productivity but ensure first-class quality too. This also leads to greater efficiency and a longer tool life – tailored geometry to the material means less wear and tear and tool breakage risks are reduced.

Using tools created for a specific application enhances reliability and provides customers unique solutions to production issues. By using bespoke tooling designed specifically for the application we aim not only to reduce cycle time but make the application more robust and reliable.

When considering a special cutting tools manufacturer, it’s important to find a company which is experienced in producing tools and which aligns precisely with your requirements for improved performance and competitiveness.

Rainford Precision has more than three decades of experience in special precision cutting tools and we pride ourselves on delivering customised tools for exceptional results.

Backed by a team of seasoned engineers, we provide unparalleled customer service, are ISO 9001 certified and operate stringent processes to achieve the highest standards of quality.

Rainford not only uses all its years of inhouse knowledge but has formed partnerships with some of the world’s leading manufacturers in precision tooling to bring this expertise to the UK. Having access to such a wide pool of global talent helps us to stay at the forefront of the latest developments and technology. This in turn translates into superior bespoke cutting tools which confer a distinct competitive advantage.

Investing in custom tools is a smart decision which will serve to enhance your workshop’s capabilities and competitiveness. It may have a higher initial cost, but this is quickly outweighed by the increased efficiency, tool life and productivity special tools bring with them.

Contact Rainford Precision today and connect with our team to transform your production process with custom-designed precision cutting tools that are crafted to your unique application.

Kern Microtechnik is well-known as one of the world’s leading manufacturers of precision CNC machining centres.

The miniaturization of turned parts, particularly when internal machining, demands completely new tool philosophies and concepts, as the ‘scaling...

The evolution of manufacturing technology has created unprecedented demand for complex, precise components across a vast range of different...